Tablet Toolings

Punches & Dies are the most vital change-parts of the tableting process. They are responsible for the final appearance and shape of the manufacturing tablets. Cadmach supplies Tablet Punches and Dies and all types of Tablet Press Tooling installed in Pharmaceuticals, Ayurvedics, Nutraceuticals & many more applications worldwide.

Cadmach has built a STATE-OF-ART plant with in-house CAD / CAM supported CNC machines with the latest manufacturing techniques available around the world for manufacturing tablet compression toolings. We use the best quality of Steel from the top world-class steel manufacturers available in the market.

Various Tooling Standards :

Cadmach has a versatile capability and knowledge of manufacturing tooling as per the following standards :

– TSM and IPT Standard

– Indian standard

– EU standard

– Special Customised Standard

Plating/Coating Applications :

CADMACH implements the world class coating solutions in order to solve tablet formation & tooling problems with different product.

HCP – Hard Chrome Plating

One of the most commonly used surface treatments is hard chrome plating which is perfect for a number of standard applications. Hard chrome increases abrasion resistance and provides an effective anticorrosive cover.

CrN – Chromium Nitride Coating

CrN coating gives excellent anti-stick performance & superb corrosion resistance.

TiN – Titanium Nitride Coating

A gold coloured TiN coating gives high wear & tear protection with very high hardness and low thermal conductivity.

Various Embossing Applications:

Cadmach is having the facility and expertise to emboss all kind of the below on the Punches and dies as per customer’s requirement:

– Alpha-Numeric letters,

– Company or Product LOGOs

– Break-lines & Notches

– Laser Marking

Special Steels Moc

The tablet tooling is exposed to high compression forces and they often compress powders of abrasive and corrosive properties. Such products always require the tooling to be made of high quality steel. The main requirements for steels used in the manufacturing of compression tooling are wear resistance, good resistance to chipping, high compressive strength and high hardness.

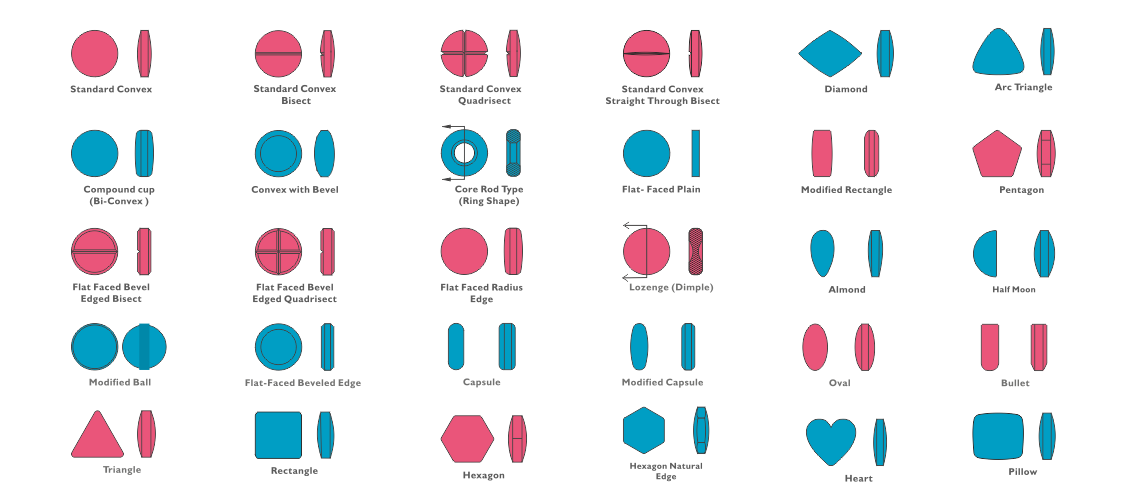

Tooling For Different Tablet Shapes